- Home

- Services

- Media Centre

- Accreditations

- Recruitment

- History

- Contact Us

- LSTC Surveys

The average age of a wooden power pole in the UK is 40 years old, and whilst a pole may look structurally sound from the outside, quite often defects and decay occur from within. In fact, around 90 percent of timber pole defects are actually below ground level.

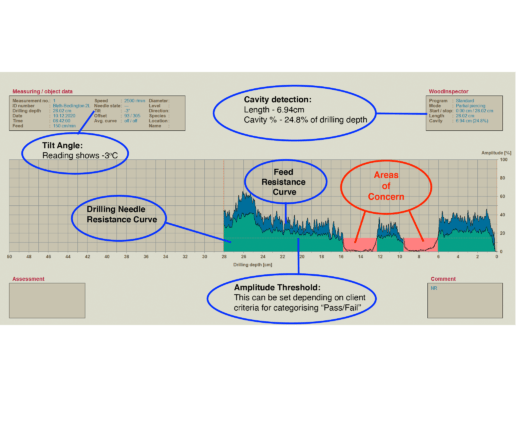

The IML Resistograph Drilling System is based on the concept of measuring drilling resistance. A drilling needle is inserted into the pole under constant drive. Whilst drilling, the amount of resistance is calculated depending on the drilling depth of the needle. Cavities, defects or decaying wood are detected by the drill exhibiting lower resistances than expected.

The Resistograph Drilling System allows us to provide you with an accurate and comprehensive condition survey of the internal and sub-ground level condition of your poles.

Using this simple but highly accurate procedure it is possible to get information about structures, inner defects and the condition of wooden poles. The obtained data is recorded electronically and then evaluated and processed on a PC with specific software.

Taking a measurement using the PD500 is as simple as placing the device against the pole in the centre position at the desired angle and pressing the start button.

Built-in technology allows for measurements to be taken under the ground line without the need for excavation – no heavy plant or excavation/lifting equipment is required.

See the simple but effective process in action here:

When uploaded to a PC, the condition of the pole can be mapped and analysed in an easy to graphical format, creating a library of condition reports for all of the poles in a network. User parameters can be preset to automatically classify the pole as a pass/fail.

DNOs can build up a library of condition reports for all of their assets. Archived reports can be analysed to assess whether a particular pole has deteriorated over time, to what extent and whether it can be repaired or if it requires replacement.

For more information:

Email us at info@lstc.co.uk or phone Martin Straker / Stuart Kay on 01377 253 617